I know that many consider me crazy, and may be I am. But my purpose of building this model sailboat is to use it to learn and apply the very many technologies that you encounter in our hobby of naval models. Known and familiar to everyone is the work with wood, with plastics like epoxy and so one. We all know about how to install servos and all the stuff that makes or models R/C controllable. Well, having worked for many years in the semiconductor and telecommunications industry, I have seen self build and developed electronics as an area were a lot of new grounds can be addressed and the dedication to this helps me to train my grey cells, something even more important know, were due to health problems I have a special need to exercise those cells so that damage done by too long period of time without oxygen supply can fix itself by reorganizing my brain. So, please be aware of, that the many years investigating, studying and experimenting with the electronics to achieve certain things in my sail boat have led to spend a lot of effort and time on topics, that while strongly related to our hobby, are fields you normally do not encounter in a step by step report on building a model. I like to say, that the way is my goal and not the finishing of the model.

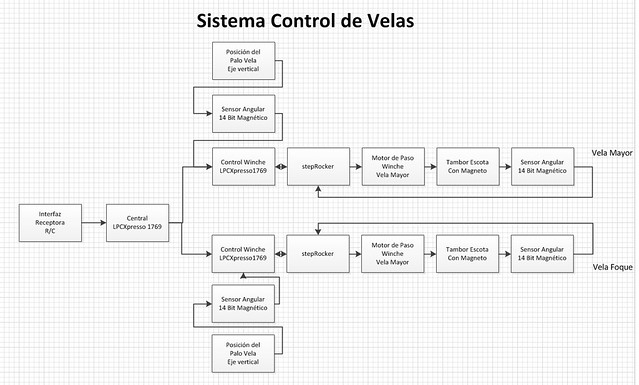

Having written the above, i have been thinking about how to organize my reporting of my work towards implementing my own mechanism for sheet control. I will assume that the reader has little background on the topic and so the report will introduce you with many pictures and some videos on the different topics, on what is the objective and how I plan to address it. The whole project is work in progress!

My goal at the beginning, I did have close to zero knowledge about sail boats, was to engage in building a sailboat opposed to sail planes that I used to build and fly, because having lost my job I wanted to need to spend little money. So I purchased the plan for a long keel sailboat and build the hull as presented in the first üart of this report. Then I learned about the beauty of sail boats of the J-Class, the Endeavour being one of them. The result of getting to know this sail boats was, that I wanted to realize a model of the kind of thise sailboats. One characteristic of those sail boats is that they have huge sail areas, something that makes models build along the example of those boats very sensitive to stronger winds. This lead to have me introduce some goals and concepts into the way I build my model to achieve the best possible results. In the plan that I used to build my hull there were 2 versions, which were different by the height of the deck. I build mine with the higher deck. Another benefit of the design of my hull is, that it is wider than the hulls of the J-Class sailboats. Finally i decided to move the waterline close to the deck achieving a higher displacement and as a consequence my test in a water pool was, that my model could have 29 kg weight. This weight is approx. more than twice of the original value!

The next aspect to take into account to make the sail boat capable to navigate with stronger winds could be reducing the size of the sails. Well, I loved the picture of the J-Class also due to the impressive sails and compared to those the sail area of the sail in the plan for my hull. I kept it unchanged, resulting in a much smaller sail area than the one you find on the Endeavour i.e., but still larger than those of normal sail boat models.

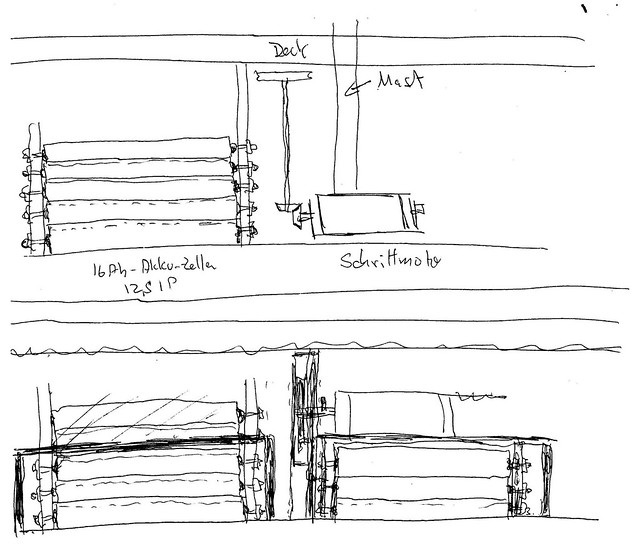

Finally the location of the center of gravity is key. I set myself the goal to achieve the lowest possible location for the center of gravity by ensuring no empty space was left empty low in the hull. The only exception to this over all rule s the deck. I had decided early in the design process of the hull, that my deck would be fully detachable, but that no compromise would be done to ensure that no water could get into the hull!

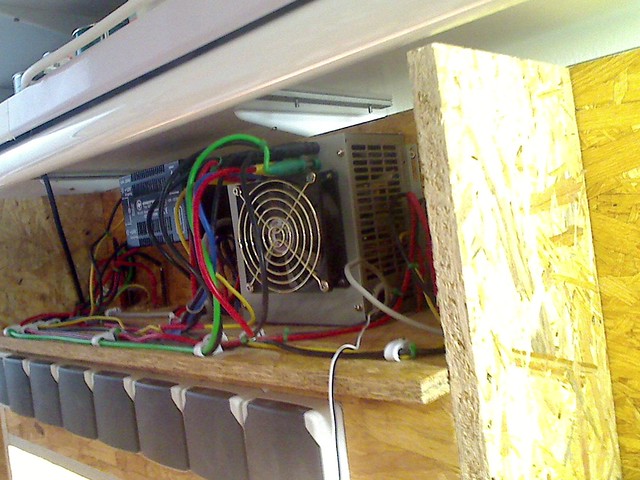

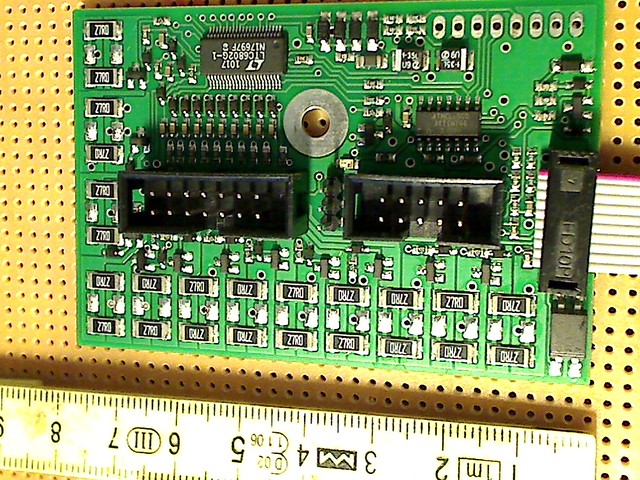

Another important factor as to why I have chosen i.e. the large battery cells in my model was the goal to ensure the maximum possible capacity of the battery to be available on board. I could not find any source that reliably would enable me to estimate the power consumption of the two large stepper motors I have planned to build into my hull as winches, 3 Nm torque each. So I wanted to be sure that when the model would be ready it could navigate with a single charge of a battery long enough for what was needed for day on the pont. I knew, that the power consumption of stepper motors was highest, when not stepping, means supplying holding torque. As the stepper motors holding the sheet without moving would be the operation mode in which the stepper motors would spend most of the time, I had to assume worst case power consumption. As my learning curve on the subject improved I decided to use electrical brakes to hoöld the stepper motor in position and as a consequence being able to power down the stepper motor. For your information. Electrical brakes of the kind used, are without power applied braking the shaft of a motor and therefore holöding it in its position. Applying 24 VDC the break releases. So the use of such electrical breaks would nearly eliminate the power consumption of the 2 stepper motors during most of its time. Still so,i decided to stick with my original goal to use batteries with the largest capacity possible.

The next thing that became evident to me was, that i was going to use batteries using a chemistry based on Lithium. I learned that there are different chemistries and the frequently used chemistries like Lipos and so on had a potential problem of catching fire. The reason why in many threads i read about this batteries it was suggested to remove them from the model for storage or charging and even to store those batteries in a fire safe container. Well, I realized pretty soon, that my batteries could not be removed easily and that as a consequence I would have to choose a chemistry with less capacity, but much more stable. I came to the conclusion to use LiFePO4 chemistry in my batteries and found a type with 16 Ah of capacity from Headway.

This battery with a diameter of 40 mm and a length of 173 mm with 16 AH was not much longer than the smaller version with just 10 Ah. Unloaded to the point were it has to be recharged the LiFePO4 cell supplies approx. 2.0 VDC, so to ensure the electrical breaks could be operated until the very end of the operating time I had to have 12 of this battery cells build into my hull. So this 2 reasons are responsible that I have 12 of this LiFePO4 batteries build into my model. I am aware that today, many years after I made the design decision, due to a much better understanding of the subject and due to dramatic development in the ICs to control stepper motors, were I have to specifically name those from the company Trinamic, energy consumption of stepper motors can be dramatically reduced with the result, that my model has an overly powerful battery pack installed, offering a capacitance much higher than required. But you all know, better too much, than to little! The weight and the space required to have those 12 cells build into my hull are not only not a problem, but effectively have a great contribution to achieve the 29 kg of weight and to ensure a low center of gravity.

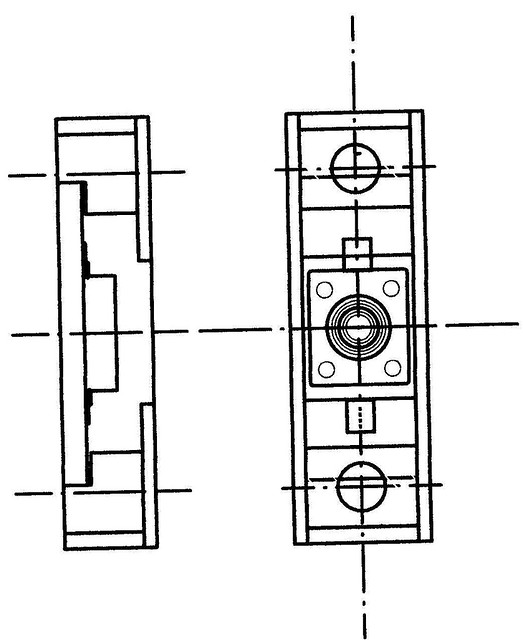

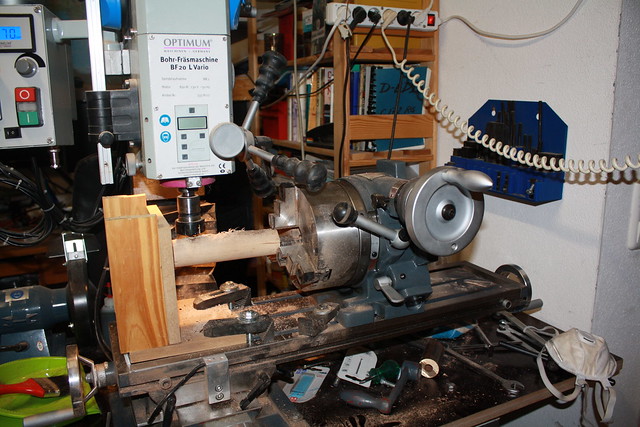

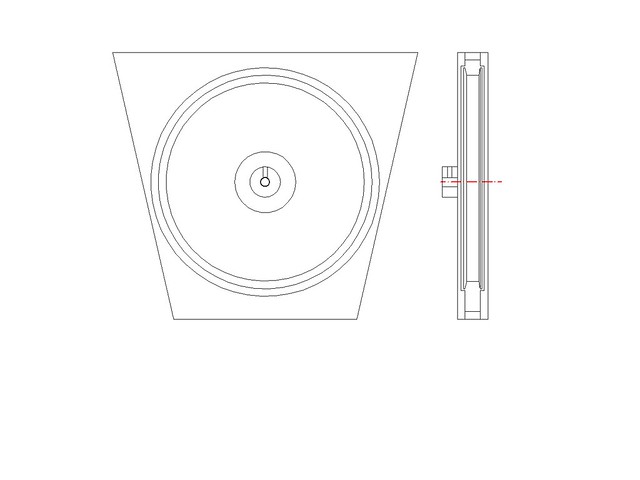

Here a picture of one of the 2 stepper motors to be used to implement the winch functionality in my sailboat. As you can see they are relatively big, the square geometry of the motor has a 63 mm length per side and about 90 mm length and a weight of approx. 1250g., totalling the contribution of both motors 2.5 kg. Each battery cell has a weight of 485 g * 12 = 5,820 kg. The sum of about 8,3kg for batteries and motors makes evident, that the proper placement of this elements in the hull would play a very important role in achieving the proper balance of weight in the hull. But, and this is typical to what I always encounter as I go into any of the many subjects related to my project, there is one more aspect to take into account.

Each battery cell has 3.6 * 16 A = 57,6 Wh of energy stored. Should i use the real batteries for the diverse works in the construction of the hull, the danger from accidental short circuits could be huge, as each cell can provide during short circuit 240 A of current + 3.6 V = 864 W of energy during up to 4 minutes. Don´t let us even think about something going wrong with all 12 cells at a time! The consequence of this is that I decided to build, what I call fake batteries:

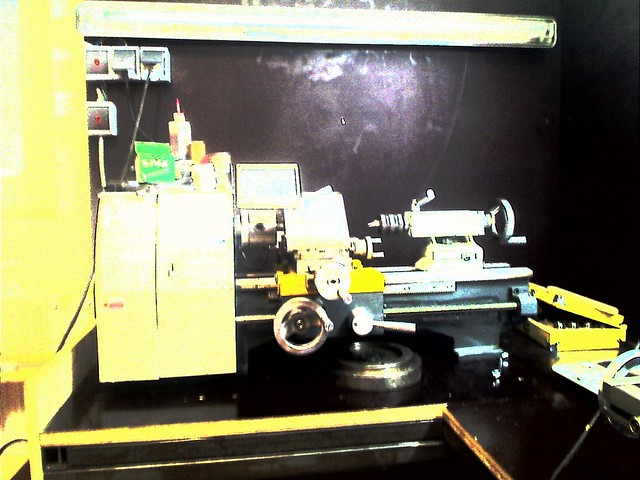

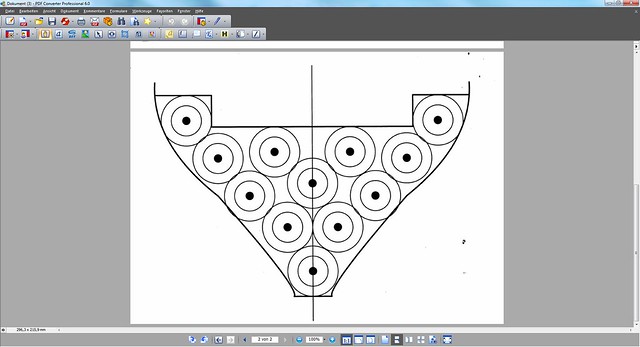

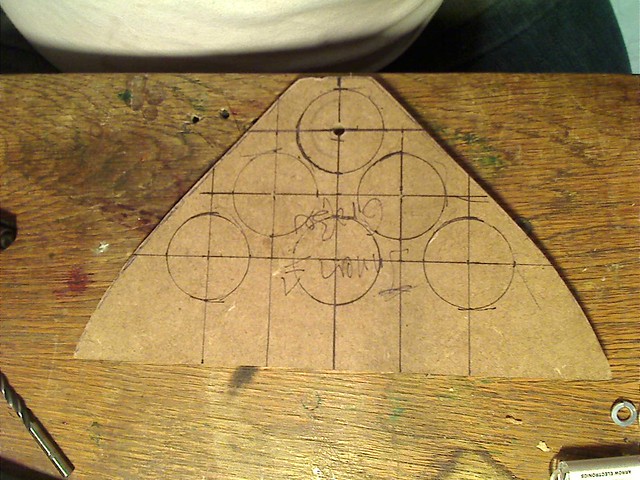

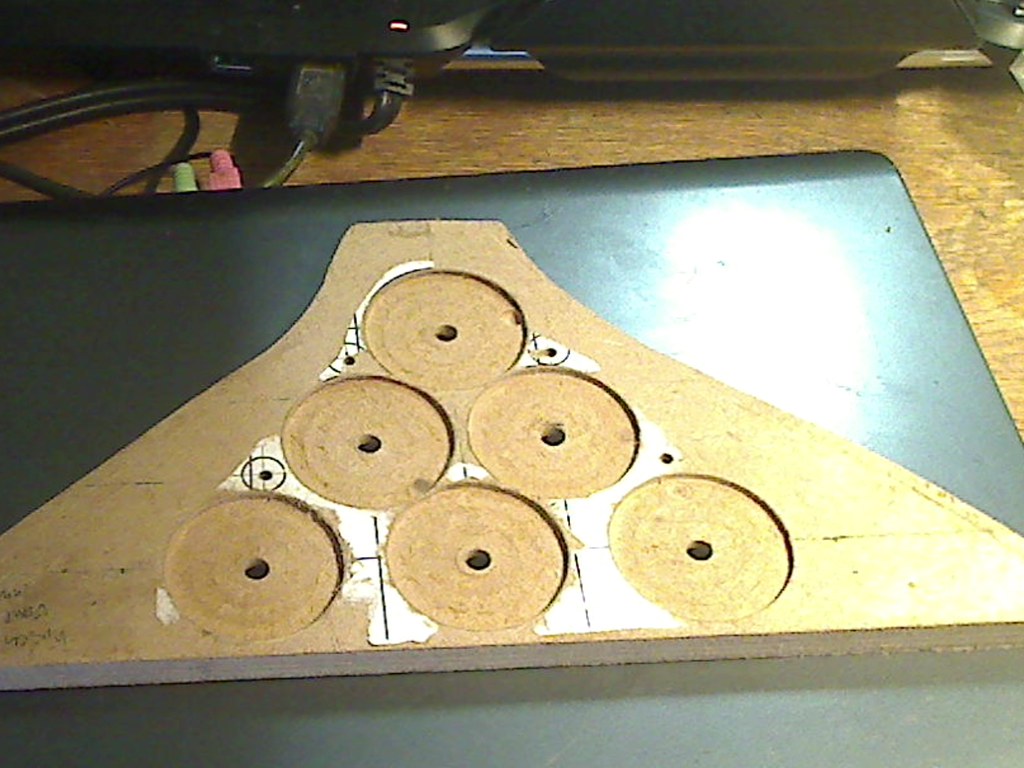

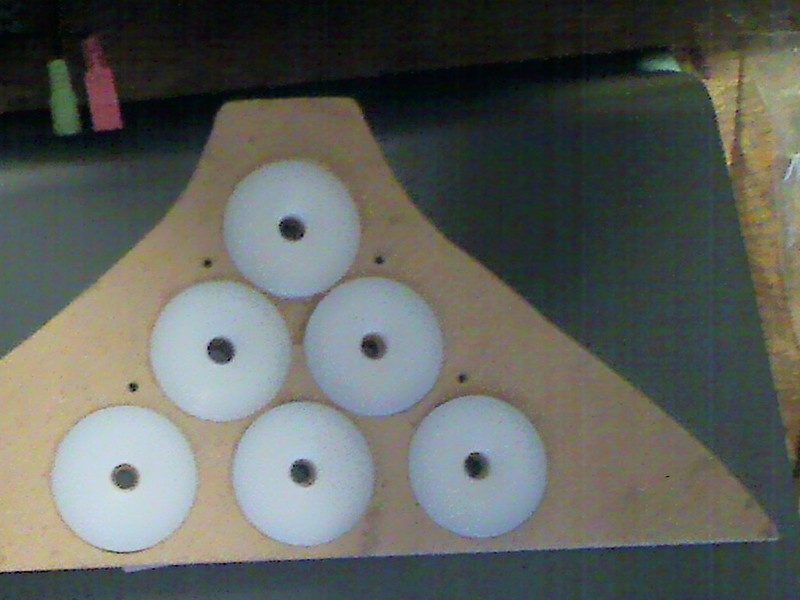

For doing this I purchased round wooden bars, 40 mm diameter and did cut pieces equivalent in length to those of the batteries. You see the on the picture. What i have not pointed out so far, is that this batteries have the very useful characteristic, to have M8 threaded holes at both ends allowing to connect the batteries via screws. So my fake batteries had to have the same threaded holes at their poles. The next aspect to fix was their weight of the fake batteries, it had to be identical to those of the original. To accomplish this I computed the amount of lead I would require to have those fake batteries to have the same weight as the original batteries and compute the volume of the amount of lead required. This defined the length, the depth and the width of the grooves, which filled with lead would help to achieve the objective. I could use the rotating device I had purchased to mill the drum I would need for the sheet.